Precision Stamping & Machining for Mission-Critical Components.

A PrecisionX Group company, Coining offers 60 years of expertise and is globally recognized as a TRUSTED Source for Coined, Stamped and Machined Metal Components, specializing in hard-alloys and complex geometries.

Join Us at Space Tech Expo 2025 – Visit Booth 408!

June 3-4, 2025, Long beach Convention Center, Long Beach, CA

Core Capabilities

Progressive Stamping

We deliver high-volume, precision metal parts through progressive stamping, ensuring consistent quality for industries like aerospace, automotive, and medical, where efficiency and accuracy are critical.

Deep Drawing

Our deep draw expertise allows us to create complex, high-tolerance metal components from durable materials, ideal for industries requiring precision and strength, such as aerospace, medical, and defense.

Swiss Machining

We specialize in Swiss machining, crafting small, high-precision components with superior accuracy and surface finishes, ideal for complex parts used in medical, aerospace, and electronics applications.

Wire EDM

We provide high-precision wire solutions for critical applications in medical devices, electronics, and telecommunications, ensuring durability, reliability, and top-tier performance.

CNC Machining

Our CNC machining services offer the flexibility to create complex, precise components across various materials, ensuring exceptional accuracy for industries such as aerospace, defense, and medical.

PrecisionX Full Capabilities

The PrecisionX Group offers a robust portfolio, including deep drawing, progressive stamping, CNC machining, Swiss machining, laser marking, laser welding, and more. With expansive facilities and expertise across multiple industries, we provide solutions for your complex manufacturing needs. Brands include: GEM, Coining, National Manufacturing, Ditron, MSK Precision Products.

Industries & Applications Served

Aerospace & Defense

In aerospace and defense, materials that perform reliably in harsh environments are essential. We specialize in high-performance metals like Inconel, Titanium, and Hastelloy, engineered to withstand extreme conditions. Our expertise ensures your parts meet strict industry standards for mission-critical success in even the toughest environments.

Medical Device

Precision is the foundation of success in the medical device industry. We manufacture your high-reliability components to meet stringent regulatory standards, ensuring accuracy, durability, and performance in life-saving devices. Our expertise in deep draw technologies and tight tolerances enables us to support the development of innovative medical solutions.

Satellite & Space

By partnering closely with our customers, we manufacture critical components that meet the extreme demands of space applications. Precision-engineered parts are essential to the performance and reliability of satellite and telecommunications systems, supporting communication, navigation, and data collection missions.

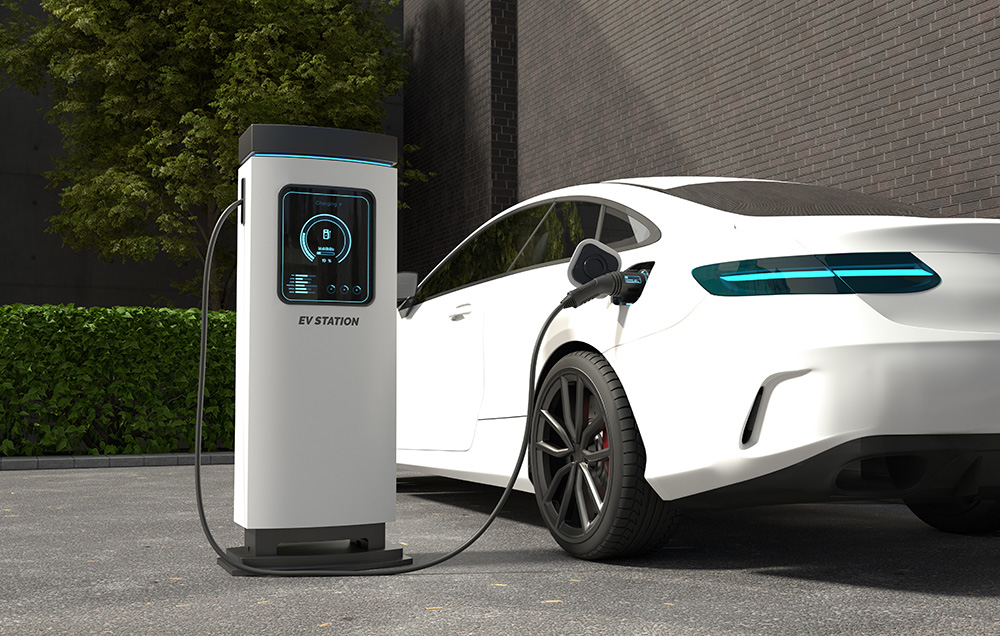

Electric Vehicle

As the need for innovation accelerates, we partner with our customers’ engineering teams to manufacture the critical components that power the next generation of EVs. From precision metal parts to advanced manufacturing solutions, we deliver excellence.

Mining

In the mining industry, precision and reliability are essential. Blasting caps and other critical components are crafted to perform in the harshest environments. By partnering with your engineers, we deliver durable, high-quality solutions that ensure efficiency.

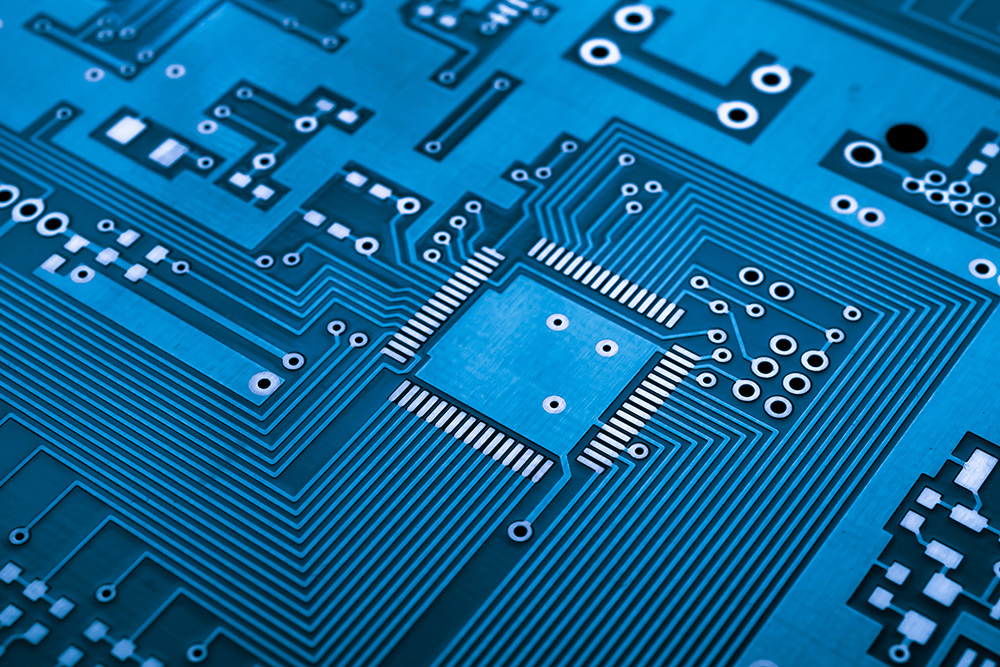

Semiconductor

Our advanced capabilities in metal forming, stamping, and machining ensure the highest quality parts for critical PCB applications. Whether it’s connectors, shields, or custom components, we manufacture to exacting specifications, providing reliable and durable solutions that enhance PCB performance.

About Us

For over 60 years, Coining has been a leading supplier of precision machined and metal stamped components for Aerospace, Defense, Medical, Telecommunications, Automotive, Semiconductor, and Hermetic Sealing industries. As a vertically integrated manufacturer, we provide Progressive Die Stamping, CNC Milling, Swiss Screw Machining, and Wire EDM, with all tools and dies crafted in-house to ensure superior quality.

As a PrecisionX Group company, our customers benefit from expanded capabilities, increased capacity, and cross-industry expertise, allowing us to deliver custom metal components with tight tolerances and advanced materials like Kovar, Inconel, and Stainless Steel. Backed by ISO 9001:2015 certification and state-of-the-art inspection equipment, we ensure precision, reliability, and excellence in every component we manufacture.

Explore Our Full Range of Materials