Best-in-Class Metal Coining & Stamping: Precision on Complex Materials & Tight Tolerances

Advanced Progressive Coining & Stamping: Precision Solutions for Complex Metal Components

Within the PrecisionX Group platform, our Micro Miniature Stamping capabilities are redefining precision manufacturing for technology-based industries worldwide. We specialize in pressure-forming nearly microscopic parts and components, leveraging advanced progressive-die stamping with speeds up to 1,600 SPM for high-efficiency production. Our refined die designs enable burr-free stamping with sub-micron precision, ensuring superior product integrity.

With expertise spanning Medical Devices, Aerospace, Military, and Electronics, PrecisionX Group delivers high-performance metal components that meet the most exacting quality, reliability, and precision standards.

Part widths up to 6”

Part lengths up to 6”

Stamping speeds up to 150 strokes per minute

Over 18 presses ranging from 20 to 175 tons

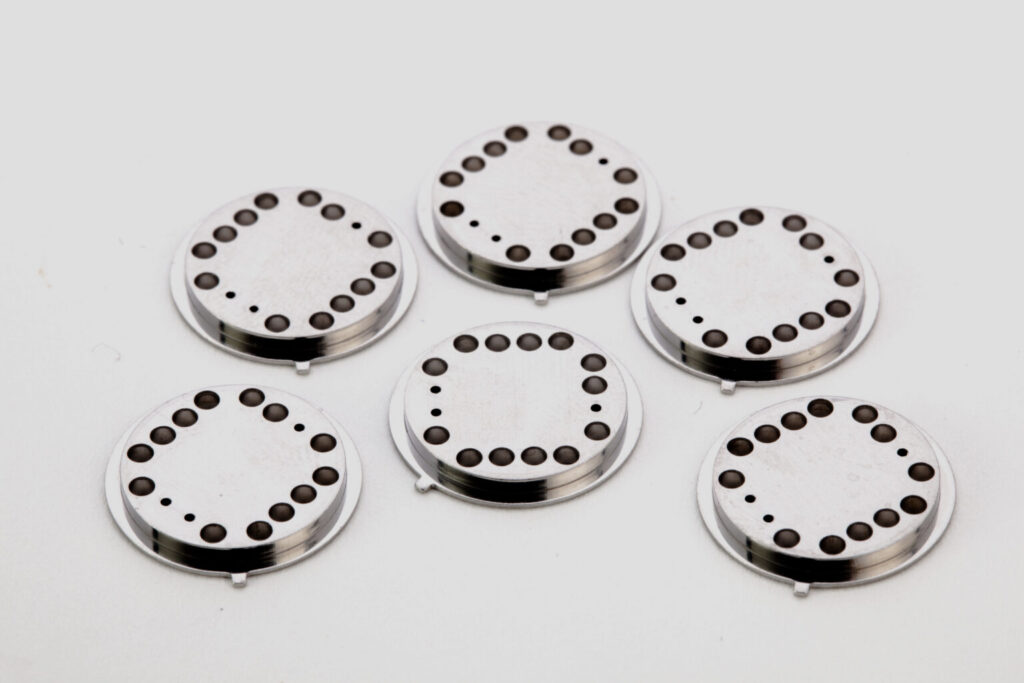

Progressive stamping ensures high repeatability, tight tolerances, and improved efficiency, resulting in shorter lead times and lower costs. All coining tools and dies are designed, built, and maintained in-house, supporting small to high volume projects with material thicknesses ranging from .003″ to .250″ and tolerances as tight as ±.0005″.

We manufacture precision parts from materials like Kovar, Stainless Steel, Copper, and more.

Stamping materials from .003” to .250” in thickness

Part widths up to 6”

Part lengths up to 6”

Stamping speeds up to 150 strokes per minute*

*Microstamping speeds up-to 1,600SPM

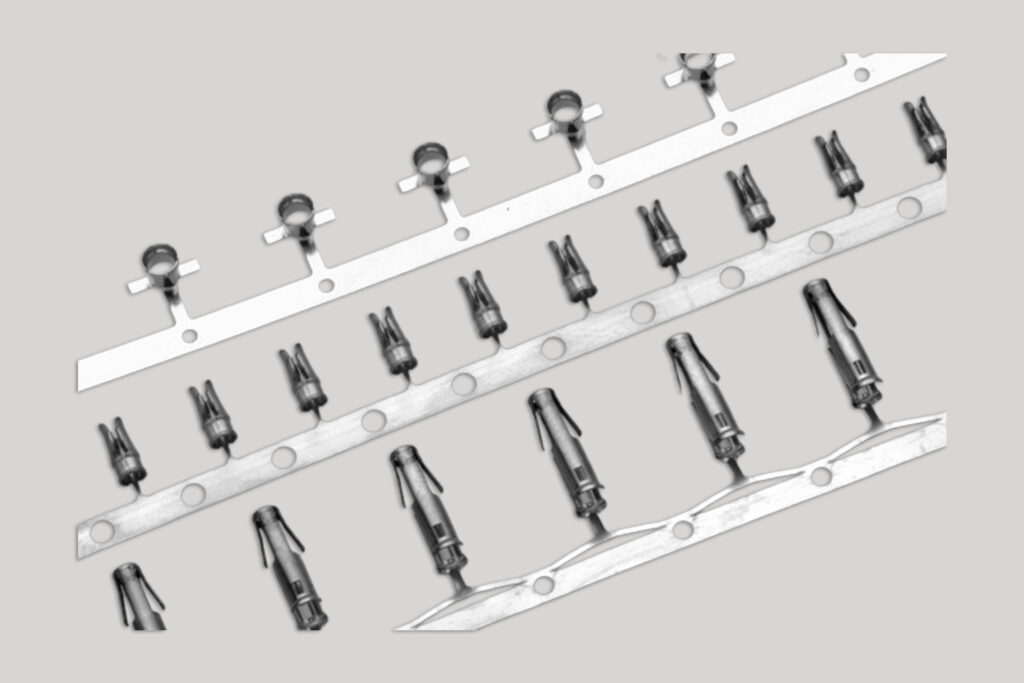

Our platform offers high-speed stamping expertise that delivers exceptional precision, efficiency, and reliability for micro electrical components used in mission-critical applications. With presses running at up to 1,600 strokes per minute (SPM), we maximize throughput and production efficiency while maintaining the strict quality and accuracy standards required for miniature and complex geometries. Our advanced progressive die stamping technology ensures that even at high speeds, each component is manufactured to exact specifications, minimizing waste, reducing lead times, and delivering high-performance solutions for medical, aerospace, defense, and electronic industries.

Single stroke stamping enables the production of complex parts with tight tolerances in a single operation, reducing the risk of material stress and defects. With its ability to maintain structural integrity while ensuring repeatability, single stroke stamping is ideal for producing high-quality components in industries where safety, durability, and performance are paramount.

At Coining’s Secondary Stamping Department, we enhance components with intricate, high-precision features through advanced secondary operations. Our capabilities include piercing, slotting, drawing, coining, trimming, tapping, and bending—all performed without sacrificing efficiency. Key service specifications include:

These capabilities ensure that we consistently deliver precision components tailored to your unique design requirements.

Unique size and tolerance capabilities.

Within the PrecisionX Group platform, our Micro Miniature Stamping capabilities are redefining precision manufacturing for technology-based industries worldwide. We specialize in pressure-forming nearly microscopic parts and components, leveraging advanced progressive-die stamping with speeds up to 1,600 SPM for high-efficiency production. Our refined die designs enable burr-free stamping with sub-micron precision, ensuring superior product integrity.

With expertise spanning Medical Devices, Aerospace, Military, and Electronics, PrecisionX Group delivers high-performance metal components that meet the most exacting quality, reliability, and precision standards.

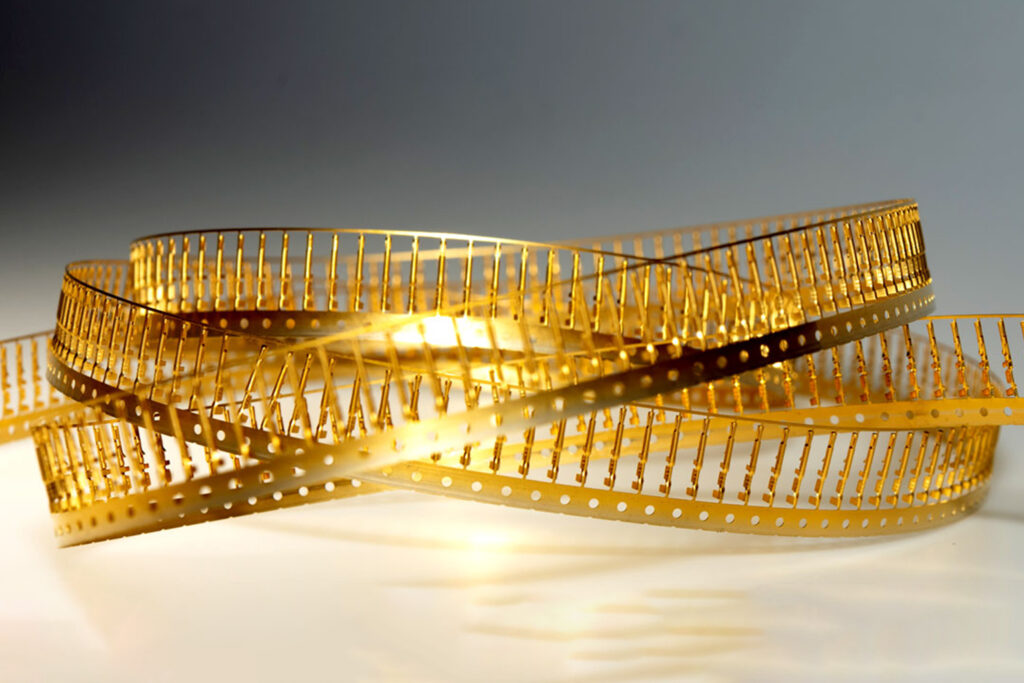

Electronic connectors, or mosquito clips, offer key benefits such as compact size, high durability, and superior conductivity due to their beryllium copper construction. They provide reliable performance in extreme environments, resist corrosion, and are suitable for both high and low voltage applications. Additionally, their precision manufacturing ensures consistent electrical connections, and they can be customized to meet specific system requirements across various industries.

Progressive stamping is an efficient and cost-effective method for producing small metal components with high precision. This process allows for rapid, high-volume production while maintaining tight tolerances and consistent quality. It minimizes material waste, reduces the need for additional machining, and supports a wide range of metals, including beryllium copper and stainless steel. Progressive stamping is ideal for creating durable, intricate parts quickly, making it a preferred solution for industries requiring precision and efficiency.

Micro and miniature stamping offers precision manufacturing of extremely small components with tight tolerances, making it ideal for industries such as medical devices, aerospace, and electronics. This process allows for the production of highly intricate parts from materials like beryllium copper, stainless steel, and other specialized alloys. With its ability to deliver consistent quality in high volumes, micro stamping is a cost-effective solution for producing complex, miniature components required in advanced applications where accuracy, reliability, and material strength are critical.

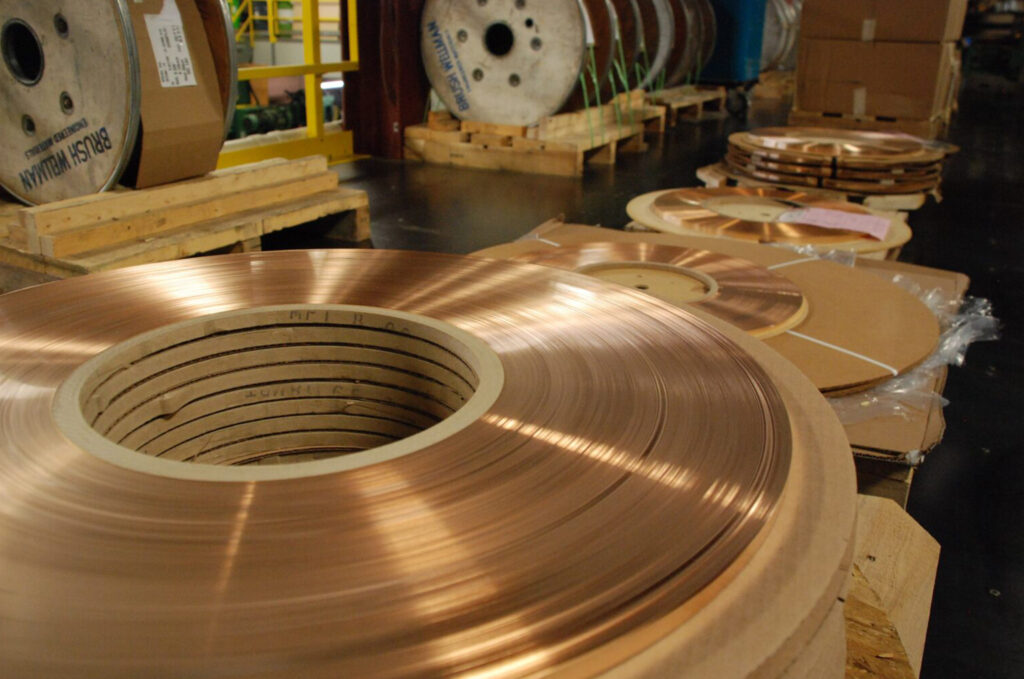

Wide range of material types

PrecisionX Group excels in forming a wide range of difficult metals, including Inconel, Nickel alloys, Hastelloy, Kovar, Titanium, and Beryllium Copper. Our expertise in stamping, deep drawing, and Swiss machining titanium, Inconel, and nickel alloys enables us to produce intricate medical devices or complex aerospace components, as well as other critical applications in satellite, space, and defense industries. With advanced techniques and in-house expertise, we shape these challenging materials with precision, meeting the tightest tolerances for critical applications. Whether it’s high-temperature resistance, corrosion resistance, or complex geometries, we deliver high-performance components with reliability and durability across the most demanding environments.

PrecisionX Group specializes in micro stamping, delivering high-precision components for industries such as aerospace, medical, and defense. Our expertise enables us to produce complex micro parts with exact tolerances, ensuring reliability and performance in critical applications. With advanced processes and the ability to work with a variety of materials, including Beryllium Copper, Kovar, and Inconel, we consistently meet the stringent demands of micro stamping for the most challenging environments.

PrecisionX Group specializes in forming difficult materials like Kovar, Inconel, and other nickel alloys, valued for their strength and resistance to high temperatures, oxidation, and chloride stress. Despite their challenging nature, our advanced techniques allow us to produce high-performance components with tight tolerances for critical applications in aerospace and electronics. We also ensure reliable metal-to-glass or ceramic seals, delivering durability and precision in the most demanding environments.

We specialize in stamping, deep drawing, and Swiss machining titanium for intricate medical devices and complex aerospace components, as well as other critical applications in satellite, space, and defense industries. Our expertise ensures high-precision components with tight tolerances, meeting the demanding standards of these sectors. With advanced technology and skilled craftsmanship, we deliver reliable, high-performance titanium solutions for complex applications.

Industries Served

Your partner in excellence.

Sitemap | Copyright © 2025. | All Rights Reserved