Micro Stamping

Crafting High-Quality, Tailored Metal Solutions with Unmatched Accuracy and Excellence

From Prototype to Production—Micro Stamping Precision You Can Depend On

PrecisionX Group sets the benchmark in micro and miniature stamping, offering unmatched size and tolerance capabilities for high-reliability applications. We specialize in producing nearly microscopic parts using advanced progressive-die technology—achieving stamping speeds up to 1,600 strokes per minute (SPM) and tolerances as tight as ±0.0005”. Our custom-engineered dies enable burr-free stamping and sub-micron precision, even in hardened, high-tensile materials such as Beryllium Copper, Phosphor Bronze, and Brass.

From early-stage prototypes to full-scale production, we support technology-driven industries including Medical Devices, Aerospace, Military, and Electronics—where consistency, complexity, and precision are non-negotiable. With PrecisionX Group, you get reliable performance from the very first part to the millionth.

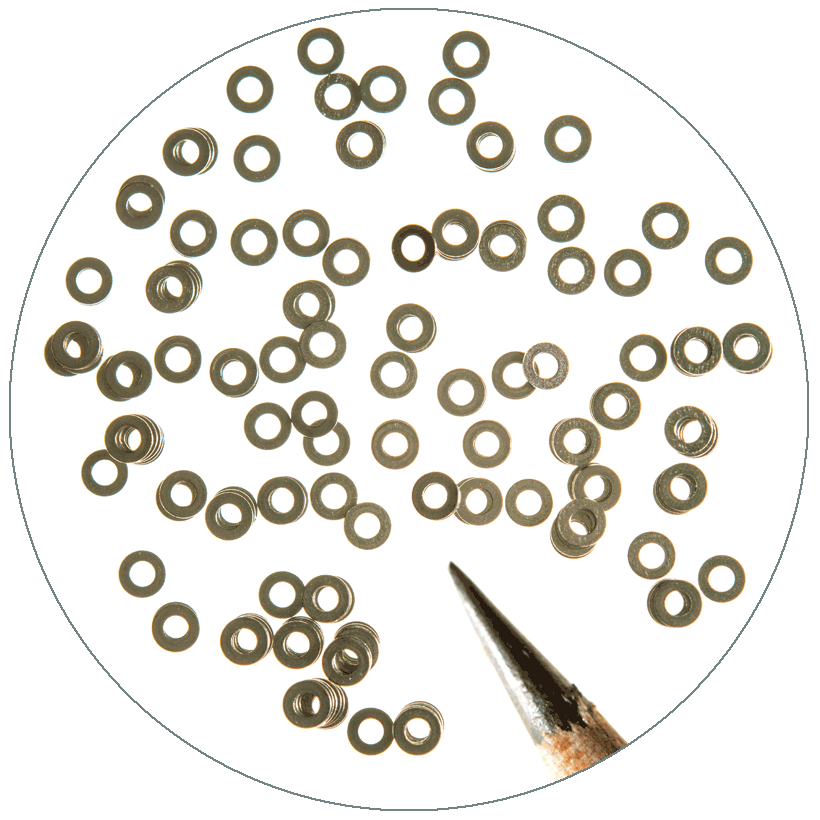

Ditron’s advanced stamping capabilities allow us to produce intricate components with diameters as small as .012 inches, maintaining exacting quality control throughout the process.

Ditron High-Speed Stamping delivers unmatched speed and precision, with presses operating up to 1,600 SPM for maximum efficiency and productivity, without compromising quality.

Unique size and tolerance capabilities.

Within the PrecisionX Group platform, our Micro Miniature Stamping capabilities are redefining precision manufacturing for technology-based industries worldwide. We specialize in pressure-forming nearly microscopic parts and components, leveraging advanced progressive-die stamping with speeds up to 1,600 SPM for high-efficiency production. Our refined die designs enable burr-free stamping with sub-micron precision, ensuring superior product integrity.

With expertise spanning Medical Devices, Aerospace, Military, and Electronics, PrecisionX Group delivers high-performance metal components that meet the most exacting quality, reliability, and precision standards.

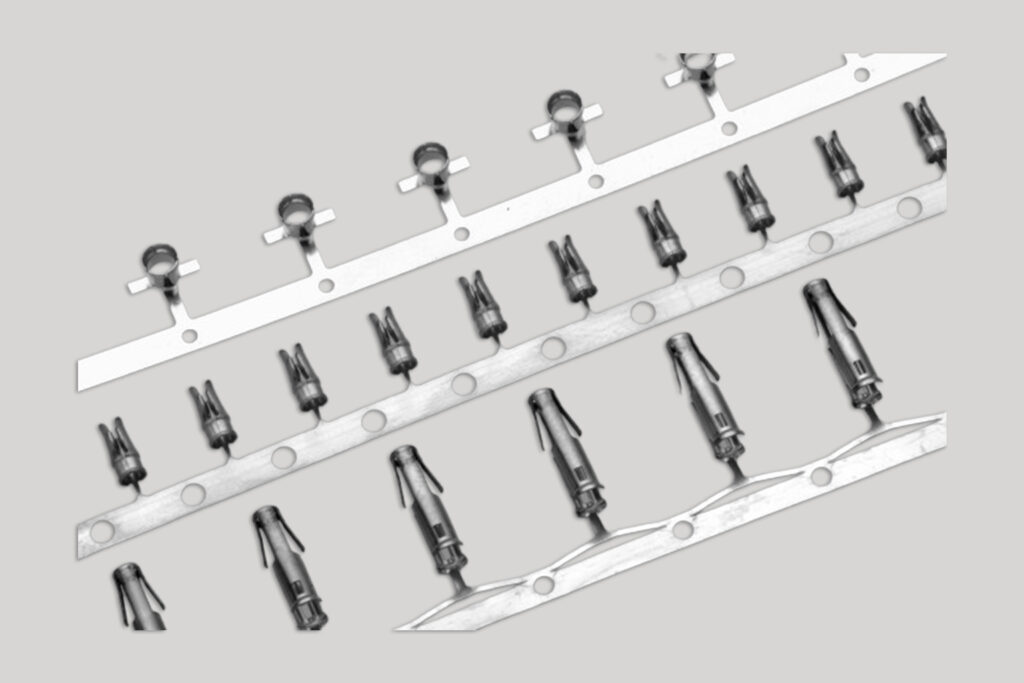

Electronic connectors, or mosquito clips, offer key benefits such as compact size, high durability, and superior conductivity due to their beryllium copper construction. They provide reliable performance in extreme environments, resist corrosion, and are suitable for both high and low voltage applications. Additionally, their precision manufacturing ensures consistent electrical connections, and they can be customized to meet specific system requirements across various industries.

Progressive stamping is an efficient and cost-effective method for producing small metal components with high precision. This process allows for rapid, high-volume production while maintaining tight tolerances and consistent quality. It minimizes material waste, reduces the need for additional machining, and supports a wide range of metals, including beryllium copper and stainless steel. Progressive stamping is ideal for creating durable, intricate parts quickly, making it a preferred solution for industries requiring precision and efficiency.

Micro and miniature stamping offers precision manufacturing of extremely small components with tight tolerances, making it ideal for industries such as medical devices, aerospace, and electronics. This process allows for the production of highly intricate parts from materials like beryllium copper, stainless steel, and other specialized alloys. With its ability to deliver consistent quality in high volumes, micro stamping is a cost-effective solution for producing complex, miniature components required in advanced applications where accuracy, reliability, and material strength are critical.

Industries Served

Your partner in excellence.

ISO 9001

AS9100

ITAR Registered