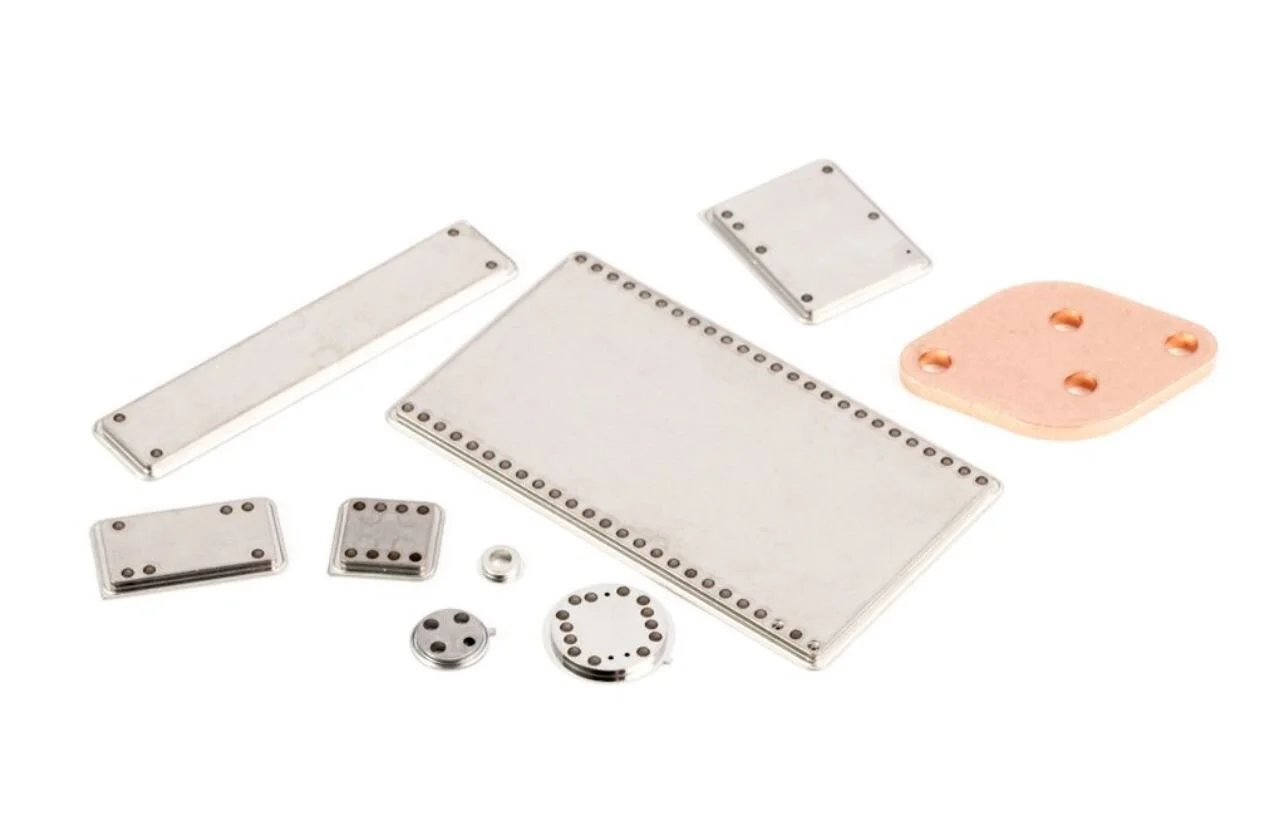

Metal Stamping and Coining

Progressive Die Stamping

As the company name suggests, Coining MFG has been a world-leading supplier of precision coined metal components for over 60 years. Progressive coining of metal components ensures high process repeatability while maintaining the tightest tolerances and improved efficiency, leading to shorter lead times and lower manufacturing costs. Coining supplies precision coined parts from a wide selection of materials including Kovar, Stainless Steel, Cold Rolled Steel, Copper, Thermocouple Alloys, Nickel, and many more. All progressive coining tools are designed, manufactured, assembled, and maintained in-house by an experienced team of Tool and Die Makers.

Coining supports small to high volume projects with materials as thin as .003” to as thick as .250” holding tolerances as tight as ±.0005” on many of the features.

Progressive Stamping Services

Stamping materials from .003” to .250” in thickness

Part widths up to 6”

Part lengths up to 6”

Stamping speeds up to 150 strokes per minute

Over 18 presses ranging from 20 to 175 tons

Deburring and tumbling processes:

Barrel tumbling

High energy tumbling

Vibratory tumbling

Secondary Stamping

Coining’s secondary stamping department is able to add many intricate and complex features without sacrificing precision or efficiency. Secondary operations include piercing, slotting, drawing, coining, trimming, tapping, and bending.

Secondary Stamping Services

Stamping materials from .003” to .187” in thickness

Part widths up to 10”

Part lengths up to 10”

Pierce rectangular slots with corner radii as sharp as .002”

Single stroke stamping ensures accuracy when manufacturing complex geometries

Deep Drawing

Coining’s 20 to 175-ton presses deep draw components as small as .003” square to as large as 2.5” square while holding tight tolerances up to +-.0005”. With a variety of high-speed press strokes, Coining draws complex, custom components at a rate of up to 100 parts per minute. Coining’s experienced Tool and Die Department produces and maintains its own carbide progressive precision dies in-house to ensure longevity and repeatability.

Coining can deep draw a part as long as two times its diameter measurement. For example, a part that is 2” in diameter can be drawn up to 4” long.

Coining’s secondary presses have the capabilities to deep draw, form, and coin parts as well as pierce and shave holes. The single and multi-stroke presses allow for more control when drawing and adding complex geometries.

Coining MFG can draw parts made out of various materials including Kovar, Nickel, Alloy-52, Copper, Alloy-42, Alumel, Stainless Steel, Chromel, CRS, and Titanium.